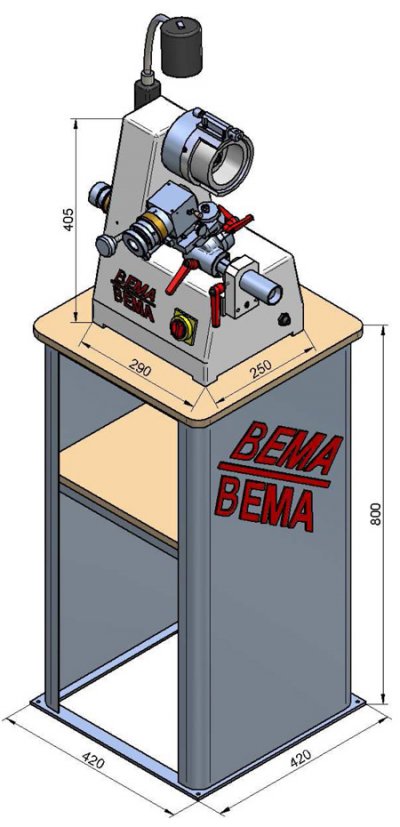

Universal graver grinding machine "BEMA 2"

Is characterised by the following key features:

- Robust machine housing with integrated motor with dust protection.

- Smooth, vibration-free running and therefore a clean grinding profile.

- Clear arrangement of controls.

- Grinding disc protection with connection for an extraction system.

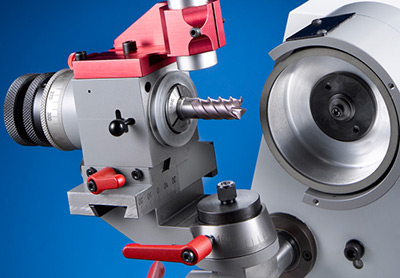

Tool holder:

The tool holder consists of a dividing head with 360° division and an additional notch division of 15°.

The button on the sleeve bearing means that the following functions can be easily and simply engaged:

- Release of the sleeve for round grinding.

- Switching into the 15° notch division.

- 180° limiting for rear grinding of the milling cutter

Cross and longitudinal carriage can be finely adjusted, enabling the precise grinding of radii from the centre an offset radii.

The Nonius scale attached to the cross carriage is used for the precise setting of one-sided concave an convex radii.

The neatly arranged radial stop on the tool holder arm enables the grinding of dovetail and conical sections up to 30°.

Drive:

The grinding disc is powered by a two-stage motor. This is also an advantage when using diamond discs. The grinding spindle is powered by a V-belt. The same is also used in the closed machine body

Color:

RAL7035 / RAL7037

Technical specifications “BEMA 2“:

- Drive motor output: 0.25KW

- Speed of the grinding spindle: 2250/4500 rpm

- Max. radius to be ground from the centre: 20mm

- Max. radius to be ground lateral, concave & convex: 20mm

- Notch number of the dividing disc: 24

- Max. rear grinding angle: approx. 45°

- Lateral fine positioning of the tool holder: approx.20mm

- Cup wheel: Ø100mm

- Division of the scale ring: 360°

Download the overview as PDF file.

Milling cutter free hand

Electrical connection CE compliant