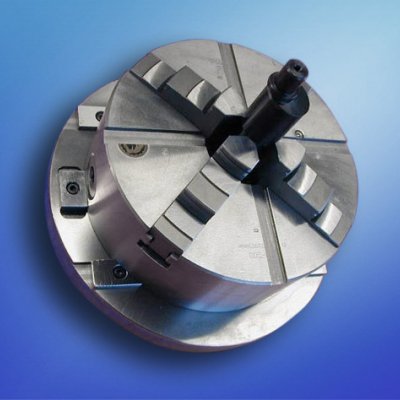

An eccentric lathe chuck which can be adjusted easily and accurately is the EXB 4 -200/50 eccentric lathe chuck. It consists of a flange fitted directly onto the spindle nose. The flange corresponds to Size 5 DIN 55027 and to a 4-jaw chuck with circumference of 200mm. The 4-jaw lathe chuck is attached to the flange by 6 bolts.

For adjusting a cam, these bolts are slackened and the chuck is pushed away from its zero dead stop.

The dimension of the cam is adjusted by inserting a block gauge between the zero dead stop and the chuck. The size of the block gauge corresponds exactly to the eccentric dimension. After that, the six bolts are refastened.

The possibility of adjusting the eccentric dimension with a block gauge means that a precision of 0.01 mm can be maintained.

By means of the markings on the chuck body material, it is possible to apply identification on the top and bottom dead centre of the cam. The direct contact between the jaws and the workpiece produces workpiece tensioning as secure as with normal centric turning.

Setting a precise eccentric dimension takes a maximum of three minutes. Using this eccentric lathe chuck, a turned part can be rotated centrally and then eccentrically without being unclamped.